Segment Information

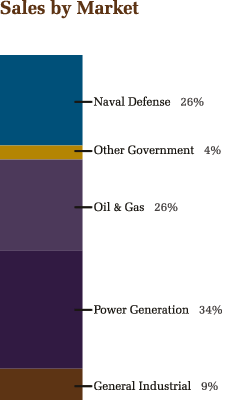

Flow Control

The Flow Control segment specializes in the design and manufacture of highly engineered valves, pumps, motors, generators, electronics, systems and related products that regulate the flow of liquids, gases and vapors in severe service environments. Divisions include:

Electro-Mechanical Systems

High-performance pumps, motors, generators, power conditioning electronics, electronic control integration and protection solutions for defense, power generation, oil and gas, and general industrial markets.

Commercial Power Services

Design, manufacture, distribution and qualification of critical components and related services for new build and operating commercial nuclear power plants, fossil-fuel power plants, hydroelectric energy producers and the U.S. Department of Energy.

Oil & Gas Systems

Design and manufacture of valves, vessel products, valve automation and control systems, coke unheading systems and fluidic catalytic cracking unit components for the oil and gas refining market.

Valve Systems

Specialized valve solutions and web-enabled software that control the flow of liquids and gases and prevent over-pressurization of vessels, pipelines and equipment for defense, power generation, process and general industrial markets; shipboard helicopter handling systems for military applications.

Control Systems

Electronic instrumentation and control equipment, including custom and commercial-off-the-shelf electronic circuit boards and systems for defense and processing markets.

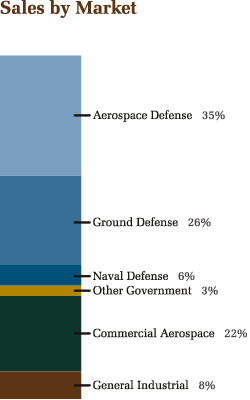

Motion Control

The Motion Control segment integrates complex elements for use in flight control, actuation, sensing and electronic computing system applications. Divisions include:

Embedded Computing

Ruggedized custom and commercial-off-the-shelf electronic boards and subsystems for high-density data processing as well as custom software design and hardware manufacturing for aerospace, ground and naval defense markets.

Engineered Systems

Flight control actuation components and systems; weapons handling systems; utility actuation; military vehicle turret aiming and stabilization; suspension systems for military vehicles and high-speed trains; rotary sensors; pilot controls for defense, commercial and industrial markets.

Integrated Sensing

Position, pressure and temperature sensors; smoke and ice detection sensors; solenoids and solenoid valves; air data computers; flight data recorders; joysticks for defense aerospace, commercial aerospace and industrial markets.

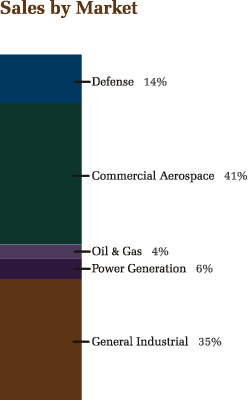

Metal Treatment

The Metal Treatment segment performs metal finishing services that enhance the performance and extend the life of critical components utilized in aerospace, automotive/transportation, power generation and general industrial markets. The four surface treatment technologies include:

Shot Peening

Round metallic or ceramic balls are directed at a metal component in a controlled manner to impart a beneficial compressive stress layer on the surface that improves the fatigue resistance and durability of the part. Shot peening is also used to shape the complex aerodynamic curvatures of the wing skins of commercial and business aircraft.

Laser Peening

A high-energy laser beam generates shock waves at the surface of a part to impart a layer of beneficial compressive stress that is four times deeper than can be achieved by traditional metal treatment processes.

Specialty Coatings

Solid film lubricant and zinc-rich coating services provide sliding wear, anti-seizing and corrosion resistance in automotive/transportation, commercial aerospace and defense applications. Parylene coating services provide lubricity, moisture barrier resistance and biocompatibility in medical device and electronic applications.

Thermal Treatment

Air, inert gas and vacuum furnaces are used to expose metal parts to controlled time and temperature cycles to improve their overall strength, ductility and other mechanical properties.