New Applications and Markets For Controls Technologies

Curtiss‑Wright’s historic association with the aerospace and defense industries made the Company a leader in solving difficult motion control challenges in extreme operating conditions. Over the years, we have used our market presence, technical innovation and resources to position ourselves at the leading edge of actuation technology. When coupled with our more recent expansion into electronic sensors, this technology portfolio puts Curtiss‑Wright at the forefront of critical mission control systems for applications ranging from turbine engine fuel management to special use remotely operated land, air, and sea vehicles.

Through strategic planning, technology development, and acquisition integration, Curtiss‑Wright is poised to broaden its global actuation and sensor products market presence, reaching beyond aerospace and into critical application industrial markets.

Since 2001, Curtiss‑Wright has taken deliberate steps to develop and accumulate a spectrum of state-of-the-art technologies that collectively transformed the Company into a leading designer and manufacturer of sensor and control systems.

Now, Curtiss‑Wright is again transforming itself through a combination of recent acquisitions, including Williams Controls, PG Drives Technology, and Exlar. These acquisitions provide us with new technologies that increase market diversification and enhance geographic expansion opportunities to help drive future growth.

One key growth initiative is to increase and expand our penetration into the market for non-automobile off-highway vehicles, which includes everything from large earth-moving equipment and agricultural tractors to medical mobility devices. Williams Controls and PG Drives Technology provide us with design and manufacturing capabilities for highly engineered electronic sensors, electronic throttle controls, and drives for off-road equipment, heavy trucks, and military vehicles, as well as for a wide variety of advanced electric-powered industrial and medical specialty vehicles.

As our sensor systems content and capabilities continue to grow and evolve, Curtiss‑Wright is better able to contribute to a wider range of our customers’ specialized engineering needs—from sensors to interfaces to process controllers to actuation.

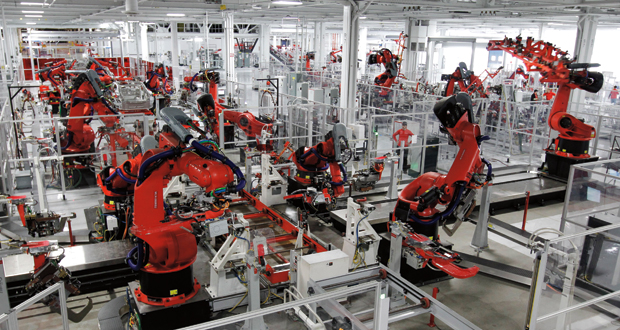

The expanded depth of our product line, the improved reach across our technology base, and the Company’s cumulative experience in solving difficult engineering challenges across many industries has transformed Curtiss‑Wright into a Tier One supplier of custom electronics for major original equipment manufacturers (OEMs). To these customers, we represent a broadly capable, cost-effective, and reliable alternative to in-house manufacturing.

We have adopted a similar diversification strategy for the actuator market. Historically, Curtiss‑Wright focused on commercial and defense aerospace. Our position in the actuator market reflected the increasingly precise demands that grew from the industry’s development of larger, faster, and infinitely more complex aerospace platforms—from jumbo jets and advanced military aircraft to space and military vehicles. On these platforms, motors for mechanical actions have become exponentially more sophisticated. In recent years, the widespread use of computers has accelerated the demand for advanced sensors to control the actuators more precisely. Over time, we have seen significant interlock develop between these two product areas.

With the acquisition of Exlar, an industry leader in industrial electro-mechanical actuation, Curtiss‑Wright has become a leading supplier of energy-efficient and environmentally friendly electric motion systems. The addition of Exlar’s “electric actuation” capability has helped transform us into a more vertically integrated systems supplier to broader end markets. The Company now offers customers a broad portfolio of components and subsystems ranging from motors, sensors, joysticks, electronic controllers and throttle assemblies to integrated motion control systems that bring together our core components into industry-leading, critical application customer solutions.

This transformation has also proven timely in our traditional aerospace market where an array of new opportunities is emerging, driven largely by demand for improved operating efficiency, environmental regulations, and energy conservation concerns. For example, a new generation of engines, both in production and in development, uses significantly more sensors to increase operational performance and efficiency while reducing exhaust emissions.

Our strategic outlook recognizes rapid changes in technology that drive greater use of innovation. Accordingly, rather than remain solely a leading provider of actuators for the aerospace market, we have chosen to become an actuator and sensor provider whose product leadership serves a much broader base of customers. Today, Curtiss‑Wright provides actuator and sensor technologies across multiple markets to fulfill the needs of numerous applications such as robotics, test and simulation, process control, and manufacturing equipment.